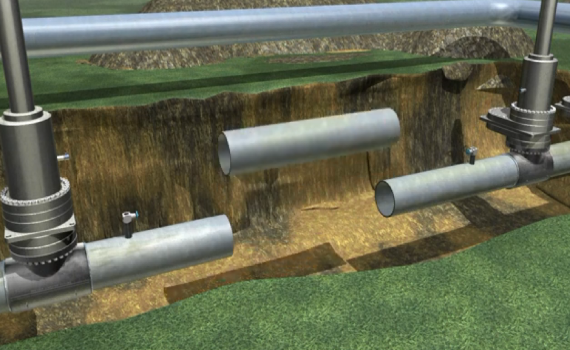

Underground Pipeline Mapping (DGPS)

DGPS is an enhancement to ‘Global Positioning System’ that uses a network of fixed ground based reference stations, to broadcast the difference between the positions indicated by the satellite systems and the known fixed positions. These stations broadcast the difference between the measured satellite pseudo ranges and actual (internally computed) pseudo ranges, and receiver stations may correct their pseudo ranges by the same amount.

Our DGPS accuracy is in millimetre because we are using RTX and RTK technique for taking the coordinate of the underground pipeline. Our accuracy level is up-to 20mm in RTX method and 8mm to 15mm in RTK mode with comparison to Geological Survey of India.